Katunwarta ta Carton

Ƙunshi

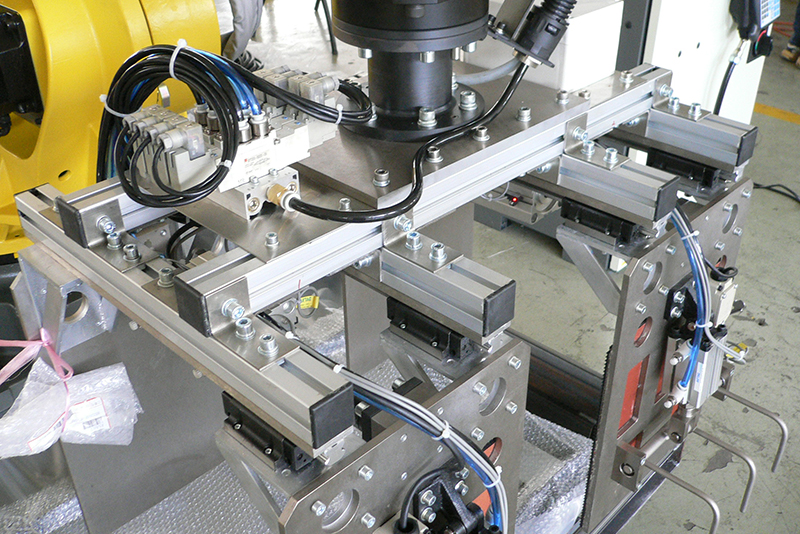

1, laburare na atomatik: tire daga shagon, jigilar kaya;

2. Watering dasawa na'urar: 90 Digiri na Mataki na Mataki da isar da matsayi;

3. Kayan sufuri na abu: Ana jigilar kayan zuwa matsayin da ya shafi matsayi;

4, pickletit na atomatik picletitis: paletelezed abu;

5. Tafiya-nauyi mai nauyi: fitarwa da sakewa bayan cikakken kaya.

Haske samfurin:

1

2, ta amfani da aikin allo na taɓawa don aiwatar da tattaunawar Man-na'urori, saurin samar da abubuwa, laifi yana haifar da wurin da yake a kallo;

3. Karewar Cardon Cardon, Strain Layer, Pallet wadata da fitarwa, mai sauƙi aiki;

5, babban pallet lafrary iya iya ɗaukar hoto, zai iya ɗaukar 8-15 a lokaci guda.

Kewayon aikace-aikace

Sanya akwatunan marasa gorassated, akwatunan filastik, farfadowa da katako, kwandon takardu, da kuma fitowar su bayan manyan motoci na atomatik, wanda ya dace da manyan manyan motoci. Adana a shagon.

Babban sigogi na fasaha

| Abu: | Kwalaye na ɓatar, akwatunan filastik, farfadawar ganga, kwandon shara, jakunkuna na takarda, jaka takarda, |

| Power / Ikon: | Tashar guda: 380v; 50HZ ± 10%; 5.5kW Dual Channel: 380v; 50HZ ± 10%; 11Kw |

| Paleting saurin (yanki / min): | Channel guda 5-16 Dual Cham 5-16 |

| Tsawon Pallet (MM): | ≤2000 (buƙatun na musamman za a iya tsara su) |

| Girman pallet l × w (mm): | (1000-1200) × (1000-1200) (Ana iya tsara takamaiman bayanai) |

| Girman injin l * w * h (mm): | Al'ada |